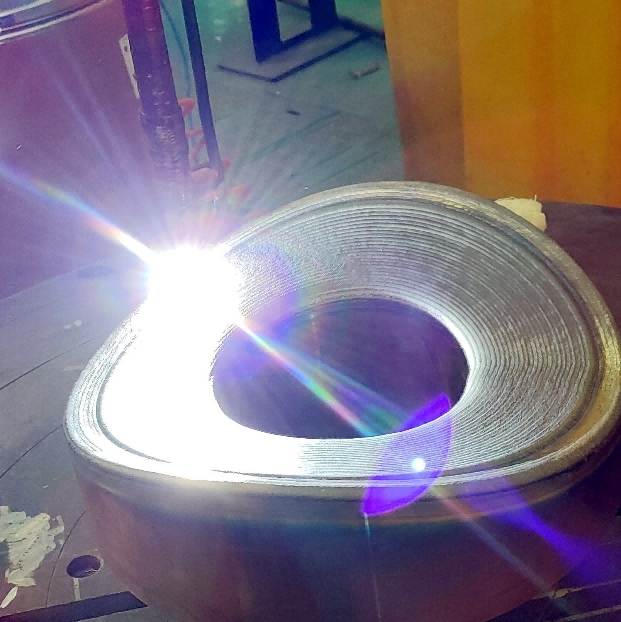

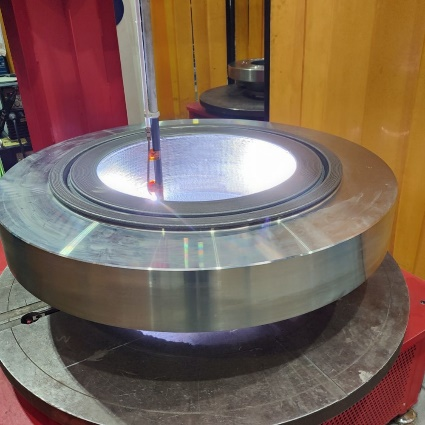

Vertical and Horizontal Cladding Station

This model is compact design, saving space and powerful. Internal and external bore, flat surface cladding and two holes 90-degree cross-section cladding are standard functions. We also provide multiple 90-degree cross-hole section, sphere borehole, multi-position one-time automatic cladding, workpiece pre-heating system, workpiece air cooling system and other optional functions, specifically according to the commercial contract options to determine the cladding function block of the whole machine.

- Overview

- Recommended Products

- Touch & retract

- Online adjust

- AVC-Arc Voltage Control

- Actual value visualization

- Remote support

- Bore-to-bore

- Data Logge

The compact type vertical & horizontal cladding station is designed for oil and gas, chemical, valve manufacturing, pressure vessels and other industries. Requirements of products with a variety of shapes can be met. This model can be used for precision welding of corrosion-resistant and wear-resistant materials.

With compact design, this model is space-saving and powerful. Configured with the basic functions of internal and external surface together with flat surface welding, this mode also boasts optional functions such as two holes 90-degree crossing intersection surface cladding, multi-bore intersection surface automatic welding, workpiece pre-heat system, workpiece cooling system, etc.

The cladding station is using TIG hot wire welding process. Suitable for automatic welding of carbon steel wire, stainless steel wire, nickel-based alloy wire, wear-resistant welding wire and other materials.

This model FIT-VHS-1600-3000 is tailored for pipe welding with 3m length and 1600mm diameter.The welding depth can achieve 3000mm. This machine includes vertical and horizontal positioners. The size of job for vertical machine: Diameter 1.4m, length 1.4m. The size of job for horizontal machine: Diameter 1m-1.6m, length 3m.

|

|

Product parameter table:

1 |

Type of Power Source |

DC Type Inverter |

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

3 |

Hot wire current Duty Cycle(40℃) |

5~150A 150A 60%; 100A 100% |

4 |

Open circuit voltage |

80V |

5 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

6 |

Input Power |

35KVA |

7 |

Inverter Cooling |

Air cooling |

8 |

Display |

5.7” TP screen handheld interface / 12” TP screen Industrial computer on control cabinet |

9 |

Data setting method |

Touch panel setting |

10 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure. |

11 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

12 |

Cooling water volume |

6L |

13 |

Manufacture Standard |

GB15579-2004 |

14 |

Insulation Safety Level /Standard |

H/IP23 |

15 |

Cladding capacity |

Vertical Size: ф50~1200mm; Height up to 1500mm, Horizontal ID: Ф168~610mm Length up to 3M |

16 |

AVC Accuracy |

±0.2V |

17 |

Recommend Peak Current |

150~280A |

18 |

Recommend Base Current |

100~200A |

19 |

Recommend Voltage |

8~16V |

20 |

Tungsten Dia. |

3.2mm |

21 |

Wire Dia. |

1.0~1.2mm |

22 |

Single Layer Thickness |

1~3mm |

23 |

Recommend gas flow rate |

12~20L/min |

24 |

Arc-starting |

HF/Contact |

Applications:

Pipe rings, Fittings, Flanges, LR bends, Valve Bodies, Valve Balls, Risers, Well head block tree valves, Pressure Vessel Components, Nozzle, Dished ends, etc.

|

|

|

|

|

|

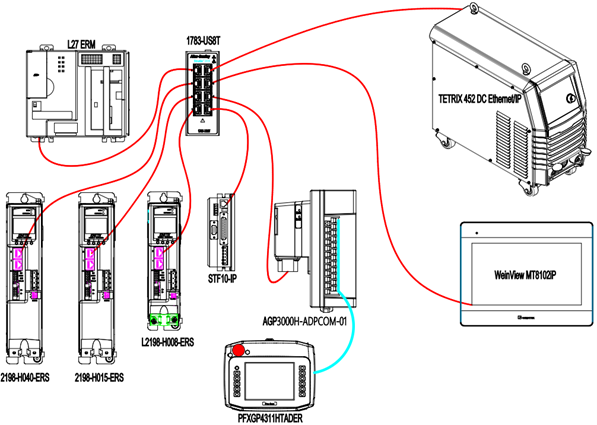

SYSTEM CONTROLLER AND REMOTE CONTROLLER

WO-ACS SERIES SOFTWARE base on

After-sales Service

After the expiration of the warranty, Supplier will carry out life-long maintenance of their products and provide a wide range of preferentical technical support in life.

During the quality assurance period, when the equipment failure in the process of use of the equipment is not resolved, Party B in the notice within 8 hours to respond, such as Customer still cannot troubleshoot, Supplier within 1 week to send maintenance engineers.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY