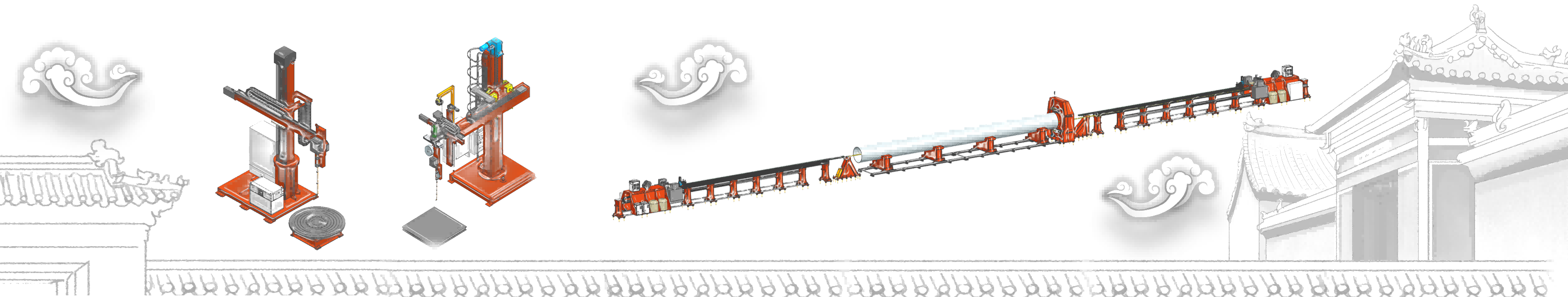

Longitudinal and Circumferential Weld TIG Equipment

This model is a special cladding station designed to cope with the application of MIG wire filling and cover welding on the longitudinal and circumferential weld of the outer wall of the pipe required by the latest longitudinal and circumferential weld pipe standard.

- Overview

- Recommended Products

- GB 15579 (the latest version)

During longitudinal welding, the welding system adopts the mode of horizontal movement of the roller frame, and the operator cannot move.

Ø In ring welding, the welding system adopts the workpiece rotation mode for welding, and the operator does not move, but only participates in welding.

Ø The welding torch head is mounted on the end of the operator beam and the special mechanism is converted into the up and down movement of the welding torch to achieve the contact of the welding torch to the workpiece and AVC tracking.

Ø The total length of the torch is 360 mm, and the vertical tracking stroke is 80 mm.

Ø Rated bearing capacity of roller frame: 40 tons, applicable pipe diameter: Φ168-Φ4000mm

Product parameter table:

|

1 |

Type of Power Source |

DC Type Inverter |

|

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

|

3 |

Hot wire current Duty Cycle(40℃) |

5~200A 200A 60%; 100A 100% |

|

4 |

Cladding Capacity |

1.3kg/H |

|

5 |

Occupied Area |

40m2 |

|

6 |

Open circuit voltage |

80V |

|

7 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

|

8 |

Input Power |

35KVA |

|

9 |

Inverter Cooling |

Air cooling |

|

10 |

Displayer |

5.7” screen Chinese/English displayer |

|

11 |

Data setting method |

Touch panel setting |

|

12 |

Display |

Touch screen/Panel/Bilingual real-time parameter display |

|

13 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure,servo error. |

|

14 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

|

15 |

Cooling water volume |

15L |

|

16 |

Cladding capacity |

Size: ф168~ф4000mm; load capacity: 40 Ton |

|

17 |

AVC Accuracy |

±0.2V |

|

18 |

Recommend Peak Current |

150~280A |

|

19 |

Recommend Base Current |

100~200A |

|

20 |

Recommend Voltage |

8~16V |

|

21 |

Tungsten Dia. |

3.2mm 4.0mm (Optional) |

|

22 |

Wire Dia. |

1.0/1.2mm 0.8mm (Optional) |

|

23 |

Single Layer Thickness |

1~3mm |

|

24 |

Recommend gas flow rate |

12~20L/min |

|

25 |

Arc-starting |

HF/Contact |

|

26 |

Manufacturing standards |

|

|

27 |

Insulation safety rating / standard |

H/IP23 |

|

28 |

Equipment size |

12m*8m*6.5m |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY