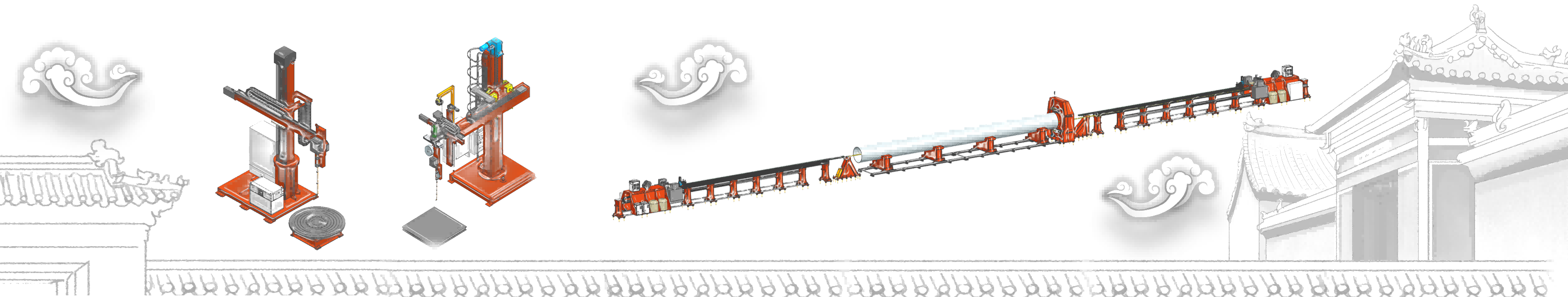

Endless Torch Rotating Cladding Station

Tack vare den intelligenta iClad 300-systemkontrollen kan komponenter med flera borrhål och olika borrhålsvinklar svetsas som standard.

Jobbstorlekar för ETR varierar från 38 till 3000mm i diameter och mindre än 3000mm i höjd. (ф38~ф3000mm, höjd upp till≤3000mm)

Alla komponenter kommer från välkända märken, såsom EWM strömkälla, Rockwell AB PLC, HIWIN, Proface fjärrkontroll, Schneider och andra.

- Översikt

- Rekommenderade produkter

- GB 15579.1to10 Bågsvetsutrustning

- JB/T 6965-1993 Svetsoperatörsram

- GB/T 1184-1996 《Formgiven Positions Tolerans》

- GB/T 10089-1988 Trädgård Cochlear Hjul, Masknoggrannhet

- GB/T 25295-2010 Riktlinjer för säkerhetsdesign av elektrisk utrustning

- GB6988-86 Elektrisk kartläggning

FITco är hedrad att tillhandahålla modell XHL-ETR beklädnadsstation som är designad för tunga och komplext formade produkter för olja & gas, kemi, ventiltillverkning, tryckkärl och andra industrier, svetsbrännaren är designad som ändlös rotation som kan uppfylla kraven för ett brett utbud av olika formprodukter.

Fitco kan specialdesigna och producera tig-svetsutrustningen enligt kundernas krav.

Tung och komplex komponentsvetsning är alltid en stor utmaning. Det är här fördelarna med FITco ETR-systemet kommer in i bilden, tack vare det intelligenta Fitco i-CLAD 300-styrsystemet har denna modell flera hål och standardsvetsning av komponenter i olika vinkel och storlekar.

Den automatiska uppriktningsfunktionen minskar avsevärt tiden som krävs för att manuellt hitta centra för traditionella tunga komponenter.

Med sin kompakta design är den rymdbesparande och kraftfull. Detta läge är konfigurerat med de grundläggande funktionerna för inre och yttre yta tillsammans med svetsning av platt yta och har även valfria funktioner som två hål 90 graders korsning av korsningsytan, automatisk svetsning av flera hål av korsningsytan, arbetsstyckets förvärmningssystem, kylsystem för arbetsstycket etc.

Utrustningens nyckelkomponenter:

Mekaniskt System: Tunglast cross operator, 3D CNC rörelsekontroll kolumn & Boomar, arbetsplattform för arbetsstycke, automatisk vattenkyltd oändligt rotande svetspistol, Valfri Servo Kontroll Rotationsbänk

Automatiskt svetskontrollsystem: svetsrörelsekontrollsystem, svetsströmförsörjning, vattenkylningssystem och skåpluftkonditionering.

Tabell över produktparametrar:

|

1 |

Typ av strömkälla |

DC Typ Inverter |

|

2 |

Svetsström Arbetscykel(40℃) |

5~450A 450A 80%; 420A 100% |

|

3 |

Hettrådsström Arbetscykel(40℃) |

5~200A 200A 60%; 100A 100% |

|

4 |

Beläggningskapacitet |

1.3kg/H |

|

5 |

Upptagen område |

20m2 |

|

6 |

Öppen krets spänning |

80 V |

|

7 |

Inmatningsspänning |

3×400V(-25%+20%) 50/60Hz |

|

8 |

Ingångseffekt |

35KVA |

|

9 |

Inverterkylning |

Luftkylning |

|

10 |

Skärm |

5,7” skärm kinesisk/engelsk displayer |

|

11 |

Datainställningsmetod |

Touchpanelinställning |

|

12 |

Display |

Touchskärm/Panel/Tvåspråkig realtidsparameterdisplay |

|

13 |

Felsökning |

Arbetsstycke kortslutning, övertemperatursskydd, överströmsskydd, överspänningsskydd, vattenbristsskydd, gasbristsskydd, strömfel, ljusbågsfel, servofel. |

|

14 |

Tändkylning |

Extern konstant temperatur cirkulerande vattenkylning |

|

15 |

Kylvattenvolym |

15L |

|

16 |

Beläggningskapacitet |

Storlek: ф38~ф3000mm; Högden upp till ≤2500mm |

|

17 |

AVC Noggrannhet |

±0.2V |

|

18 |

Rekommenderad toppström |

150~280A |

|

19 |

Rekommenderad basström |

100~200A |

|

20 |

Rekommenderad spänning |

8~16V |

|

21 |

Tungstensdiam. |

3.2mm 4.0mm (Valfritt) |

|

22 |

Tråddiameter |

1.2/1.6mm 1.0mm (Valfritt) |

|

23 |

Enskiktstjocklek |

1~3mm |

|

24 |

Rekommenderad gasflödeshastighet |

12~20L/min |

|

25 |

Bågstartande |

HF/Kontakt |

|

26 |

Tillverkningsstandarder |

|

|

27 |

Isolationssäkerhetsklass / standard |

H/IP23 |

Tillämpningsprodukter

Rörringar, Fittings, Flänsar, LR-böjar, Ventilkroppar, Ventilkulor, Stigare, Brunnsblocksträdsventiler, Tryckkärlskomponenter, Munstycke, Toppade ändar, etc.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY