TIG+MIG Butt-sveisestasjon

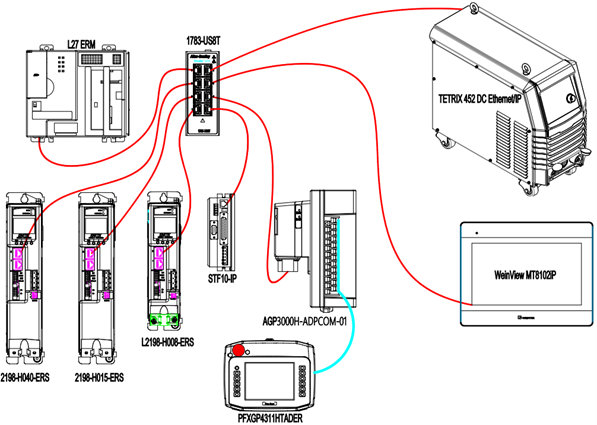

Utstyret vårt tar i bruk den mest avanserte og mest stabile digitale kommunikasjonsprotokollen Ethernet/IP, som sikrer stabilitet og rettidig intern kommunikasjon av utstyret, men forbeholder også det mest pålitelige grensesnittet og den mest praktiske kommunikasjonsprotokollen for brukere for å oppnå digitalisering på fabrikknivå i fremtiden.

- Oversikt

- Anbefalte produkter

- Berøring & tilbaketrekning

- Online justering

- AVC-Arc Spenningskontroll

- Faktisk verdi visualisering

- Fjernsupport

- Bore-til-bore

- Data Logge

FIT-FAB-I-S-12M er en argon lysbue sveise arbeidsstasjon, den er spesielt utviklet for skjøtesveising av store stål rør og tilbehør (stål rør, bøyer, flenser, T-stykker, varierende diametre, osv.). Bruksområde 1-12m lengde stål rør og flens /1.5 bøye/T-stykke/variabel diameter av den ytre ringfugen argon lysbue skjøtesveising; Anvendelig arbeidsstykke diameter Φ200mm ~ 1000mm.

Arbeidsstasjonen bruker en fast chuck roterende drev-klemmemekanisme for å drive rotasjonen av stålrøret, fire grupper av mobile ruller for å dra rørfittingen, den gående sveiserammen flyttes til støtsveiseposisjonen, sveisepistolen ved modulsving, sporing å realisere stumpsveising av rør og flenser, albuer, tees, endre diameter.

Produktparametertabell:

|

Punkt |

Teknologi parameter |

|

|

Inngangsspenning |

380V±10% 50±1Hz Tre-fase Fem-leder |

|

|

Sveisestrømforsyning |

Phoenix 650 puls TETRIX 200 SMART HOT WIRE |

|

|

Sveiseprosesser |

GTAW: Sveisevaluta: 5A-550A Driftssyklus (40℃): 420A 100 % |

|

|

GMAW Sveisevaluta: 5A-550A Driftssyklus (40℃): 420A 100 % |

||

|

SAG Sveisevaluta: 20A-650A Driftssyklus (40℃): 60 % 590A; 100 % 500A |

||

|

Miljøtemperatur |

-20℃~50℃ |

|

|

Arbeidsstykke Spesifikasjon |

Rørdiameter |

φ63~610mm |

|

Veggtykkelse |

3~70 mm |

|

|

Lengde |

200~6000mm |

|

|

Materiale |

Karbonstål, legert stål, rustfritt stål, lavtemperaturstål, kledningsrørspoleprodukter. |

|

|

Fasvinkelkrav |

Sporform V, Dobbel V-formet, U-formet Type, I Type, U-form med smal spalte, Fasvinkel 3~ 37,5° |

|

|

Sveiseform |

Ulike rørseksjoner støtomkretssveiser og sett inn innvendige og utvendige kilsveiser, som rør - rør, rør - albue, rør - flens, rør - tee, rør - stort (lite) hode, flens - rør - flens, flens - albue, etc. Flenser inkluderer: navflens og flatsveisede flenser. |

|

|

Utstyrsstrukturskjema |

Delt type: Selvsentrerende chuckdrivmekanisme med tre kjever er fullstendig adskilt fra sveiseoperatøren, og kan gå langs sporet elektrisk for å lette lasting og lossing av røret, forover og bakover. |

|

|

Sveiseoperasjonsmaskin |

Kolonne |

Effektivt slag Kjøremodus: servomotor + trapesformet skrue + lineær styreskinne |

|

Stråle |

Effektivt slag Kjøremodus: servomotor + kuleskrue + lineær styreskinne |

|

|

Chassis |

Størrelse Kjøremodus: frekvensomformer + rulle + skinne |

|

|

Drivsystem |

Kjøremodus |

Servomotor, reduksjon, chuck driver rørrotasjonen. |

|

Lastekapasitet |

Vertikal vekt 2 tonn, eksentrisk vekt 100kg. |

|

|

Max. dreiemoment |

≥2000N.m |

|

|

Rotasjonshastighet |

0,05-2rpm, trinnløs justerbar (3KW servomotordrift) |

|

|

Chuck senterhøyde |

≤1000 mm |

|

|

Kontrollsystem |

Kontrollprogramvare |

Rockwell PLC-kontroll og kontrollprogramvaren inkluderer 10 sett med modne sveiseprosessprogrammer, og maksimal lagring av 50 sett med sveiseprosessprogrammer. |

|

Fjernbetjening |

Pro-Face Manual operatør HMI dialoggrensesnitt. |

|

|

Passord |

Kontrollsystemet kan administrere passord for å skille brukertillatelser. |

|

|

Autolagring og strømbruddminne |

Systemet har automatisk lagring og strømbrudd minnefunksjon, som kan forhindre risikoen forårsaket av strømbrudd. |

|

|

Innstillingsområde for sveiseparameter |

Arbeidsstykkets rotasjonshastighet 0-1000mm/min, skrålengde 5-30mm, sveisesvinge 0-20mm, svinghastighet: 0~300mm/min, venstre og høyre holder seg ca. 0-3s, forhåndsinnstillinger og finjustering er tilgjengelig. |

|

Sveisestrømforsyningssystem:

· Argon lysbue strømforsyning TETRIX 452 DC DC pulserende argon buesveising strømforsyning produsert av det tyske EWM selskapet. Sveisemaskinen har gode mekaniske egenskaper, stabil og pålitelig kontinuerlig drift, og dens pulsfunksjon oppfyller de tekniske kravene til overflatesveising.

· TETRIX 200 SMART HOT WIRE strømforsyning fra EWM brukes.

· Egenutviklet vannkjølt automatisk TIG sveisebrenner, nominell strømføringskapasitet 300A, holdbar, god beskyttelseseffekt.

· Den har god lysbue stabilitet ved både høy lysbue spenning og lav lysbue spenning.

· Strømforsyninger designet for kommunikasjon ved bruk av de fleste standardprotokoller som TCP/IP (LAN), CAN, osv., kan kommunisere direkte med en PLC.

SYSTEMKONTROLLER OG FJERNKONTROLLER

WO-ACS SERIE PROGRAMVARE basert på

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY