Stazione di rivestimento dei tubi

Le stazioni di rivestimento dei tubi utilizzano il processo di saldatura a filo caldo TIG. Adatto per la saldatura automatica di filo di acciaio al carbonio, filo di acciaio inossidabile, filo di lega a base di nichel, filo di saldatura resistente all'usura e altri. Viene utilizzato principalmente per la parete interna di tubi lunghi 12 metri anticorrosione per tubi in acciaio laminato a caldo, tubi in acciaio senza saldatura, rivestimento del diametro interno di tubi forgiati da 130 mm a 850 mm.

- Panoramica

- Prodotti Consigliati

- -Toccare e ritrarre

- -Regolazione online

- -AVC-Controllo della tensione dell'arco

- -Visualizzazione del valore effettivo

- -Supporto remoto

- - Da foro a foro

- -Registro dati

FITco è onorata di fornire la stazione di rivestimento modello XHL-PCS progettata per tubi e recipienti per petrolio e gas, chimica, produzione di valvole, recipienti a pressione e altre industrie.

L'attrezzatura è principalmente utilizzata per la saldatura anti-corrosione della parete interna di tubi di meno di 12,5 m, il tubo di saldatura è azionato dalla rotazione del mandrino cavo finale, la torcia di saldatura è guidata da un cavo d'acciaio e attrezzature di guida per il posizionamento e completa saldatura nel canale.

È adatto per il rivestimento di tubi in acciaio laminato a caldo, tubi in acciaio senza saldatura, tubi forgiati.

diametro interno da 130 mm a 850 mm.

È alimentato da EWM Germania TETRIX 452 alimentatore di saldatura a impulsi DC e dal TETRIX 200 alimentatore di filo termico Hot Wire.

APPLICAZIONE

- Diametro del pezzo: φ850mm diametro esterno massimo, 140mm diametro interno minimo (dopo il rivestimento)

- Lunghezza del pezzo: fino a 12,5 m

- Spessore della parete del pezzo: da 9,53 a 80 mm

- Peso del pezzo: fino a 5t

- Materiale del tubo: API 5L Gr.B, X52, X60, X65, acciaio inossidabile, acciaio CrMo, ecc.

- Materiali e specifiche dei fili: ERNiCrMo-3, ERNiFeCr-1, ER316L, ER2209, ERCCoCr-E, ERCCoCr-A, ERNi1, ERCuNi diametro filo s1,2mm;

- Forma della bisella: saldatura della parete interna senza pendenza

- coppia di gruppi di bisella: nessuna;

- Posizione di saldatura: saldatura in posizione 1G (pistola di saldatura immobilizzata, rotazione del pezzo)

- Metodo di saldatura: filo caldo TIG

- Requisiti di riscaldamento: in base al processo di saldatura, il sistema non è configurato per riscaldare il sistema.

- Requisiti di ispezione dello strato di saldatura: 100% di stratificazione UT/100% di PT

- pezzi tipici: tubi di acciaio laminati a caldo, tubi di acciaio senza cuciture, tubi di forgia, ecc.

Tabella dei parametri del prodotto:

|

1 |

Tipo di fonte di alimentazione |

Invertitore di tipo CC |

|

2 |

Corrente di saldatura Ciclo di lavoro ((40°C) |

5450A 450A 80%; 420A 100% |

|

3 |

Corrente di filo caldo Ciclo di lavoro ((40°C) |

5200A 200A 25%; 150A 60%; 140A 100%. |

|

4 |

Tensione di circuito aperto |

80 V |

|

5 |

Tensione di ingresso |

3×400V ((-25%+20%) 50/60Hz |

|

6 |

Potenza di ingresso |

60 KVA |

|

7 |

Raffreddamento dell'inverter |

Raffreddamento ad aria |

|

8 |

Visualizzazione |

interfaccia portatile Touch Panel da 5.7” / touch Panel da 12” sul Cabinet di Controllo |

|

9 |

Metodo di impostazione dei dati |

Impostazione del pannello tattile |

|

10 |

Rilevazione di errore |

Corto circuito del pezzo di lavoro, protezione da sovratemperatura, protezione da sovracorrente, protezione da sovratensione, protezione da mancanza d'acqua, protezione da mancanza di gas, errore di alimentazione, guasto dell'arco. |

|

11 |

Torcia |

Torce Doppie con raffreddamento ad acqua circolante a temperatura costante esterna con chiller |

|

12 |

Volume dell'acqua di raffreddamento |

6L |

|

13 |

Norma di fabbricazione |

GB15579-2004 |

|

14 |

Livello di sicurezza dell'isolamento/norma |

H/IP23 |

|

15 |

Capacità di rivestimento |

OD : Φ168 ~ Φ850mm / 6 a 32 Pollici Identificazione minima 140 dopo l'abbigliamento. Lunghezza: Max 6500mm a 12500mm secondo l'ordine di acquisto |

|

16 |

Tasso di deposito ((2 Torcia) |

Max 4 Kg/ora per un'operazione stabile a lungo termine. Capacità fino a 6 kg/ora (secondo le condizioni di macinazione dei tubi, la rettitudine e il diametro) |

|

17 |

Velocità di Viaggio di Overlay |

Fino a 1200mm/Min |

|

18 |

Velocità di alimentazione del filo |

Fino a 5 M/min |

|

19 |

Accuratezza AVC |

± 0,3V |

|

20 |

Raccomandazione di corrente di picco |

150 ~ 280A |

|

21 |

Raccomandazione di corrente di base |

100~200A |

|

22 |

Voltaggio raccomandato |

8 ~ 16 V |

|

23 |

- Il tungsteno. |

3,2/4,0 mm |

|

24 |

Diametro del Filo e Dimensione della Bobina |

1,2/1,6 mm bobine BS 300 da 15kgs (Φ300xW104xC53mm) o 250 kg di filo di saldatura a canna |

|

25 |

Spessore di uno strato |

1 ~ 3 mm |

|

26 |

Tasso di flusso di gas raccomandato |

12~20L/min |

|

27 |

Avvio ad arco |

HF/Contact |

|

|

|

|

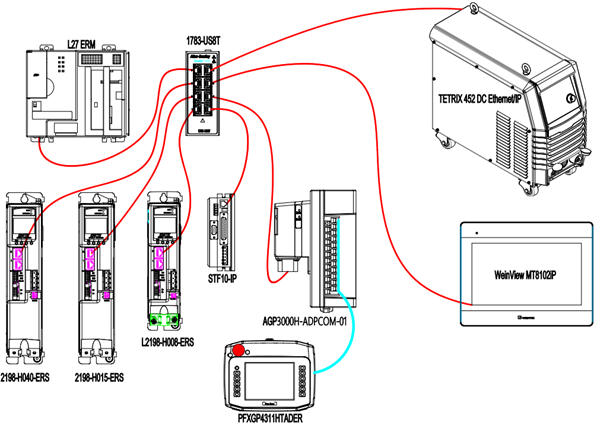

Controllo del sistema e controllo remoto

Sistemi di programmazione WO-ACS

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY