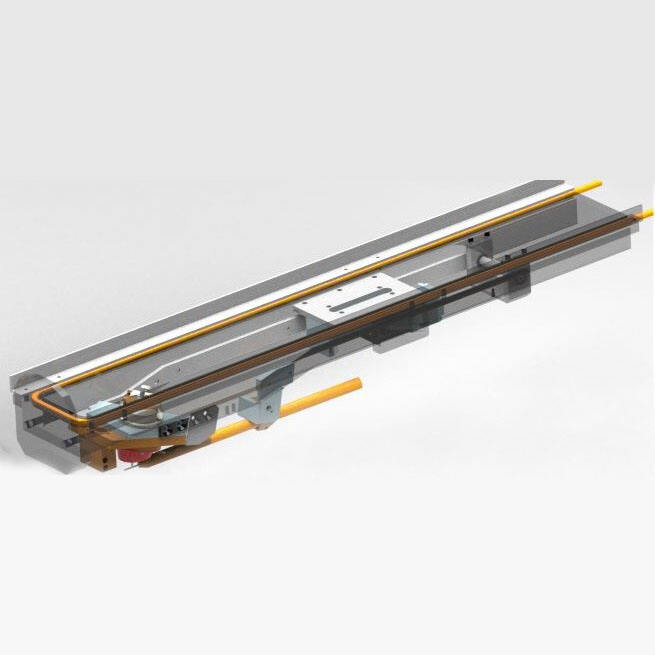

Horizontal Pipe Inner Wall Straight Seam TIG Equipment

This model is specially designed to cope with the application of MIG remelting or wire filling and cover welding of the root for the straight seam of the inner wall of the welded pipe required by the latest straight seam welded pipe standard. This model is compact, space saving and powerful. GTAW process is adopted to be suitable for automatic reflow welding or wire filling and cover welding of carbon steel wire, stainless steel wire, nickel base alloy wire and other wires.

- Overview

- Recommended Products

- GB 15579 (the latest versio)

Straight seam welding system adopts the mode of horizontal movement of the workpiece for welding, and the welding gun system is fixed on the base of the tail.

Ø The welding torch head is installed on the high rigid round tube, and the linear motion of the linear module driven by the stepper motor and the special mechanism are converted into the up and down movement of the welding torch, so as to realize the contact of the welding torch to the workpiece and AVC tracking.

Ø The welding torch has automatic arc voltage tracking function, when the welding torch and surfacing surface deviation, it can adjust automatically in time.

Ø The welding gun including the whole head is cooled by temperature-controlled forced circulating water, which can realize long-term continuous welding.

It is powered by EWM Germany TETRIX 452 DC pulse arc welding power supply and the TETRIX 200 Hot Wire thermal wire power supply.

Product parameter table:

|

1 |

Type of Power Source |

DC Type Inverter |

|

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

|

3 |

Hot wire current Duty Cycle(40℃) |

5~200A 200A 60%; 100A 100% |

|

4 |

Cladding Capacity |

1.3kg/H |

|

5 |

Occupied Area |

40m2 |

|

6 |

Open circuit voltage |

80V |

|

7 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

|

8 |

Input Power |

35KVA |

|

9 |

Inverter Cooling |

Air cooling |

|

10 |

Displayer |

5.7” screen Chinese/English displayer |

|

11 |

Data setting method |

Touch panel setting |

|

12 |

Display |

Touch screen/Panel/Bilingual real-time parameter display |

|

13 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure,servo error. |

|

14 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

|

15 |

Cooling water volume |

15L |

|

16 |

Cladding capacity |

Size: ф168~ф1500mm; load capacity: 10 Ton |

|

17 |

AVC Accuracy |

±0.2V |

|

18 |

Recommend Peak Current |

150~280A |

|

19 |

Recommend Base Current |

100~200A |

|

20 |

Recommend Voltage |

8~16V |

|

21 |

Tungsten Dia. |

3.2mm 4.0mm (Optional) |

|

22 |

Wire Dia. |

1.2/1.6mm 1.0mm (Optional) |

|

23 |

Single Layer Thickness |

1~3mm |

|

24 |

Recommend gas flow rate |

12~20L/min |

|

25 |

Arc-starting |

HF/Contact |

|

26 |

Manufacturing standards |

|

|

27 |

Insulation safety rating / standard |

H/IP23 |

|

28 |

Equipment size |

26m*1.6m*1.6m |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY