ETR Cladding ACDC TIG Welder Equipment

The intelligent iClad 300 system control enables components with multiple boreholes and different borehole angles to be welded as standard.

Job sizes for ETR range from 38 to 3000mm in diameter and less than 3000mm in height. (ф38~ф3000mm, height up to≤3000mm)

All components are from well-known brands, such as EWM power source, Rockwell AB PLC, HIWIN, Proface remote control, Schneider and others.

- Overview

- Recommended Products

- Base material:A105、A350 LF2、A694 F42~F70、AISI 4130、30CrMo,SS304/304L、SS316/316L、SS410、F51、F55,WCB、LCB casting or forged materials;

- Weld Consumables:ERNiCrMo-3、ERNiFeCr-1、ER316L、ER2594、ERCCoCr-E、ERCCoCr-A、ERNi1、ERCuNi wire;

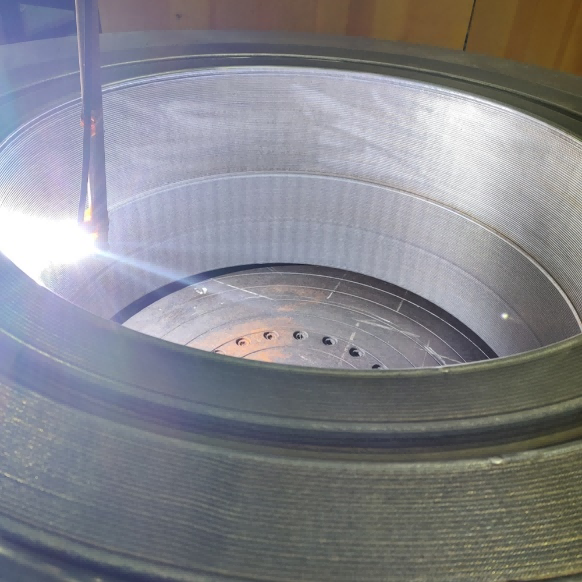

- Clad thickness: 1~3mm/layer,multilayer cladding,standard clad thickness will be 3.2mm, FL+2mm dilution will be less than 5%;

- Quality requirements:Liquid Penetrant Testing as per ASTM E165 & ASTM V requirements. First time yield for intersection surface cladding will be >95%, bore or flat surface cladding will be >98%, ring groove cladding will be >96%。

- Welding process:GTAW hot wire;

- Welding Position:2G or 1G typically.

- GB 15579.1to10 Arc Welding Equipment

- JB/T 6965-1993 Welding Operator's Frame

- GB/T 1184-1996 《Shape Given Position Tolerance》

- GB/T 10089-1988 Garden Cochlear Wheel, Worm Accuracy

- GB/T 25295-2010 Guidelines for the Safety Design of Electrical Equipment

- GB6988-86 Electrical Mapping

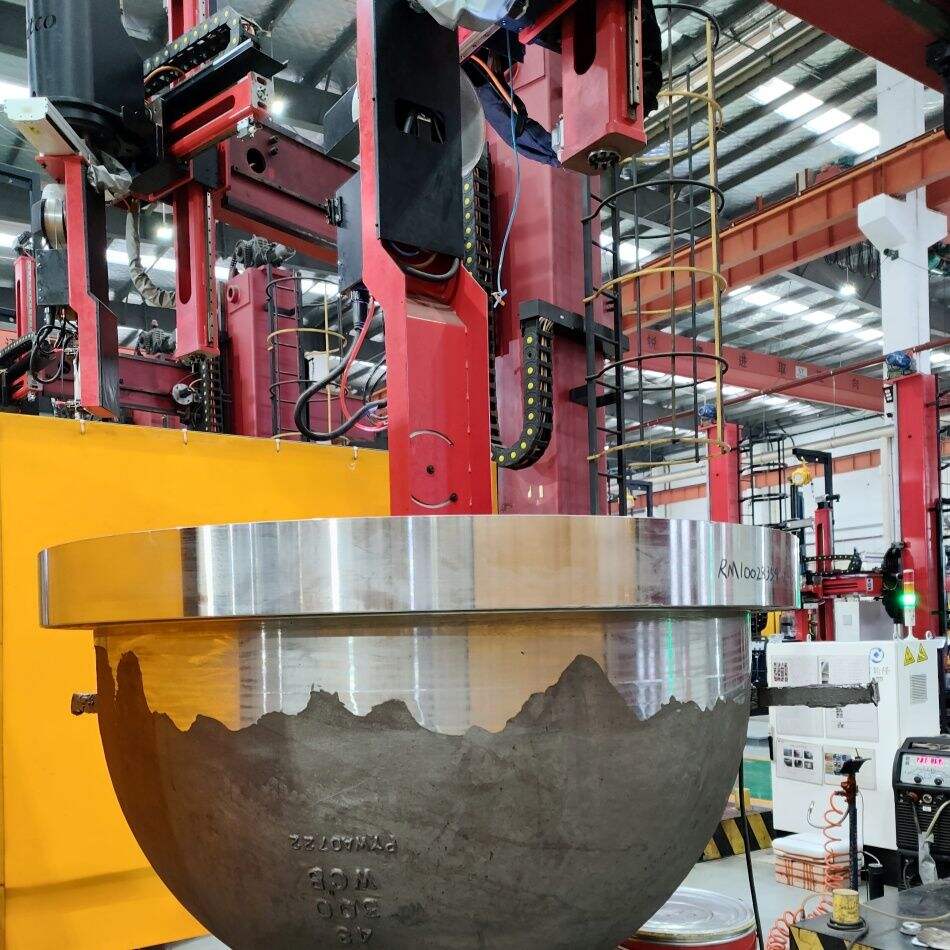

We are honored to provide model XHL-ETR cladding station which is designed for heavy and complex shaped products for oil & gas, chemical, valve manufacturing, pressure vessels and other industries, the welding torch is designed as endless rotation which can meet the requirements of a wide range of different shape products. This machine can be used for precision welding of corrosion-resistant materials and wear-resistant materials.

Heavy and complex component welding is always a huge challenge. This is where the advantages of the FITco ETR system come into play, thanks to intelligent Fitco i-CLAD 300 control system, this model features multiple holes and standard welding of components of different angles and sizes. The automatic alignment function significantly reduces the time required to manually find centers for traditional heavy components.

This model is compact design, saving space and powerful. Internal and external bore, flat surface cladding and two holes 90-degree cross-section cladding are standard functions. We also provide multiple 90-degree cross-hole section, sphere borehole, multi-position one-time automatic cladding, workpiece pre-heating system, workpiece air cooling system and other optional functions, specifically according to the commercial contract options to determine the cladding function block of the whole machine.

Automatic welding equipment for the inner wall of the valve uses a non-melting pole pulse TIG hot wire filling wire filling welding process. Suitable for carbon steel wire, stainless steel wire, nickel-based alloy wire, wear-resistant wire, and other automatic welding.

Applications:

|

|

Technical Parameters:

|

1 |

Type of Power Source |

DC Type Inverter |

|

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

|

3 |

Hot wire current Duty Cycle(40℃) |

5~200A 200A 60%; 100A 100% |

|

4 |

Cladding Capacity |

1.3kg/H |

|

5 |

Occupied Area |

20m2 |

|

6 |

Open circuit voltage |

80V |

|

7 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

|

8 |

Input Power |

35KVA |

|

9 |

Inverter Cooling |

Air cooling |

|

10 |

Displayer |

5.7” screen Chinese/English displayed |

|

11 |

Data setting method |

Touch panel setting |

|

12 |

Display |

Touch screen/Panel/Bilingual real-time parameter display |

|

13 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure,servo error. |

|

14 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

|

15 |

Cooling water volume |

15L |

|

16 |

Cladding capacity |

Size: ф38~ф3000mm; Height up to ≤2500mm |

|

17 |

AVC Accuracy |

±0.2V |

|

18 |

Recommend Peak Current |

150~280A |

|

19 |

Recommend Base Current |

100~200A |

|

20 |

Recommend Voltage |

8~16V |

|

21 |

Tungsten Dia. |

3.2mm 4.0mm (Optional) |

|

22 |

Wire Dia. |

1.2/1.6mm 1.0mm (Optional) |

|

23 |

Single Layer Thickness |

1~3mm |

|

24 |

Recommend gas flow rate |

12~20L/min |

|

25 |

Arc-starting |

HF/Contact |

|

26 |

Manufacturing standards |

|

|

27 |

Insulation safety rating / standard |

H/IP23 |

Application Products

Pipe rings, Fittings, Flanges, LR bends, Valve Bodies, Valve Balls, Risers, Well head block tree valves, Pressure Vessel Components, Nozzle, Dished ends, etc.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY